Pipelines are a necessity without which the drainage system fails to work. However, if these pipelines are not installed with the proper equipment, they might not work properly. When you install a pipeline, there is air already trapped inside it. It tends to rise and reaches the high points of the system that can cause several pipeline problems. These problems include corrosion, pump failures, flow issues, water hammer surges, and incorrect instrumentation readings. Moreover, if there is the unnecessary air pressure in the pipelines, the pump might not work properly, which ultimately results in energy consumption.

In most cases, people think that the air preserved in the pipelines is because of the installation issues. Others think that it is because of supplemental equipment; however, sometimes, it is simply because the air hasn't been removed from the line properly.

Therefore, air release pumps are used to eject the trapped air from the pipeline. This ultimately affects the performance of the pipeline, letting it flow the water smoothly.

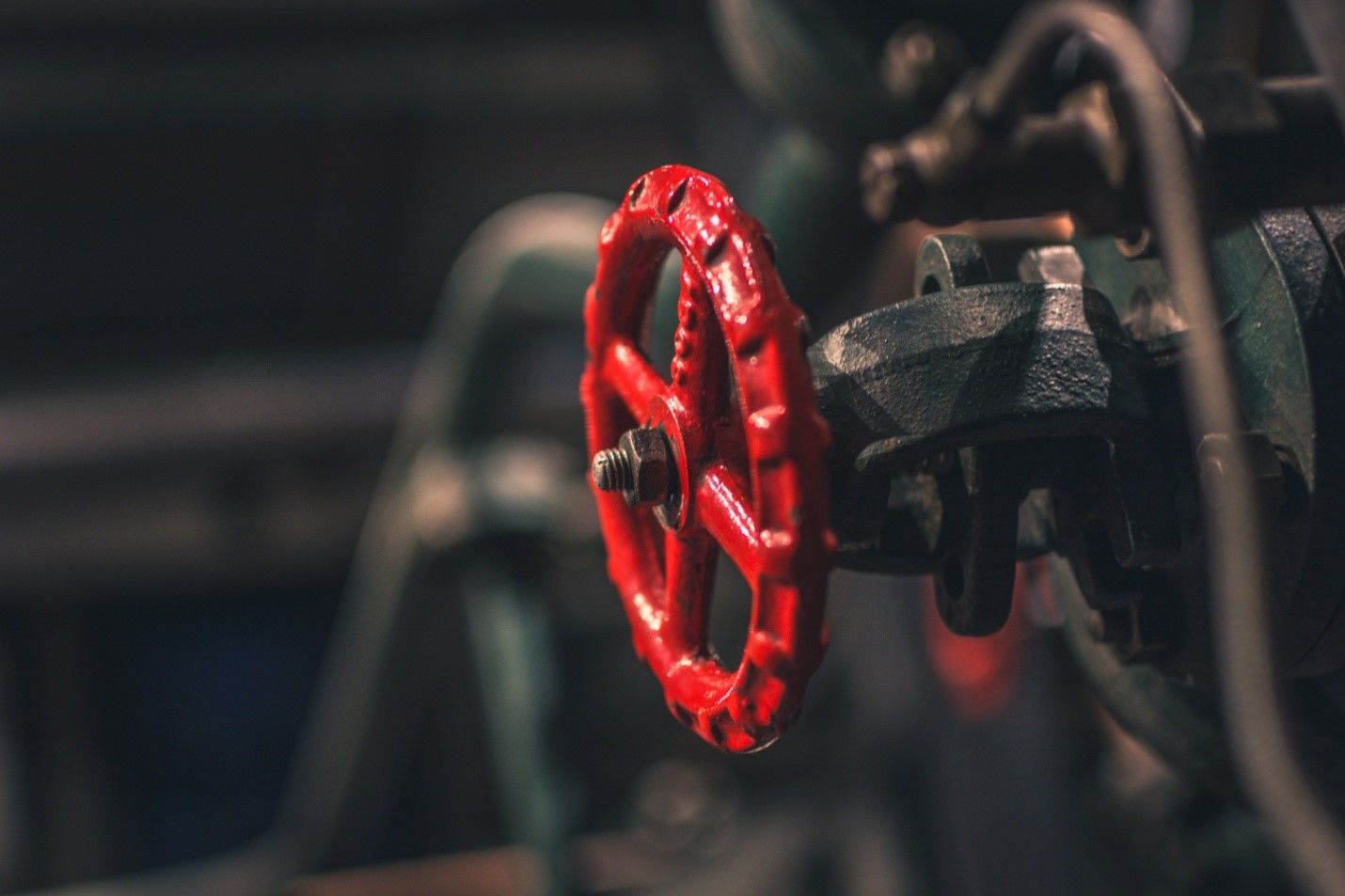

Types of Air Valves

Here are the types of air valves and their purposes:

1. Air Release Valves

Air release valves are the most popular among all the valves. These valves consist of a leverage apparatus, small cavities, and heavy floats. All these features help expel the trapped air with force when combined, releasing the air pressure. Air release valves are installed in the high points of the pipeline. Naturally, air rises and sets camp at these points. These valves let the air release as a result of compressed pressure.

2. Vacuum valves

Vacuum valves manage the pressure inside the pipeline. They are also responsible for the pipeline's safety as they protect it against all sorts of collapses and other pipeline damages. When the air gets heavy inside the pipeline, these valves help release it. When the required air is absent, these valves take in the air. Vacuum valves are mostly used in factories.

3. Combination Air Valves

As the name suggests, combination air valves are an amalgamation of air release valves and vacuum valves. They collect the excess air settled on the high points of a pipeline like air release valves and take in or release large air deposits as vacuum valves do. The combination air valves possess the qualities of both valves.

Get your hands on a combination air valve made of dual body format because it has two parts that work independently, vary from each other. Air release valves are the highlight of a pipeline, without which it cannot perform its job well. The compressed air trapped inside the pipelines can hinder the water flow and cause other damages to the entire body.