A pinch valve is a two-way piece of equipment that works like a tap and shuts off or controls the flow of any media passing through it with an on/off function. The media flowing through can be corrosive, abrasive, or granular. A pinch valve typically consists of three main components. These components include hose or body, rubber sleeve inside the body to close it, and the end connections. The operating mechanism of the valve is separate from the media flowing through, so it stays safe from corrosion or contamination by the fluid. It shuts off by pinching off a rubber tube.

How Does a Pinch Valve Work?

In air-operated punch valves, it has two endings and a rubber sleeve. It utilises air pressure to open or close the valve. When there is a pressurised air supply in the valve's body, it pushes down onto the rubber sleeve, which collapses and shuts off the valve. There is no need for an additional operator. When the air supply is disrupted and the volume of air decreases, the rubber hose opens due to the force of the process flow.

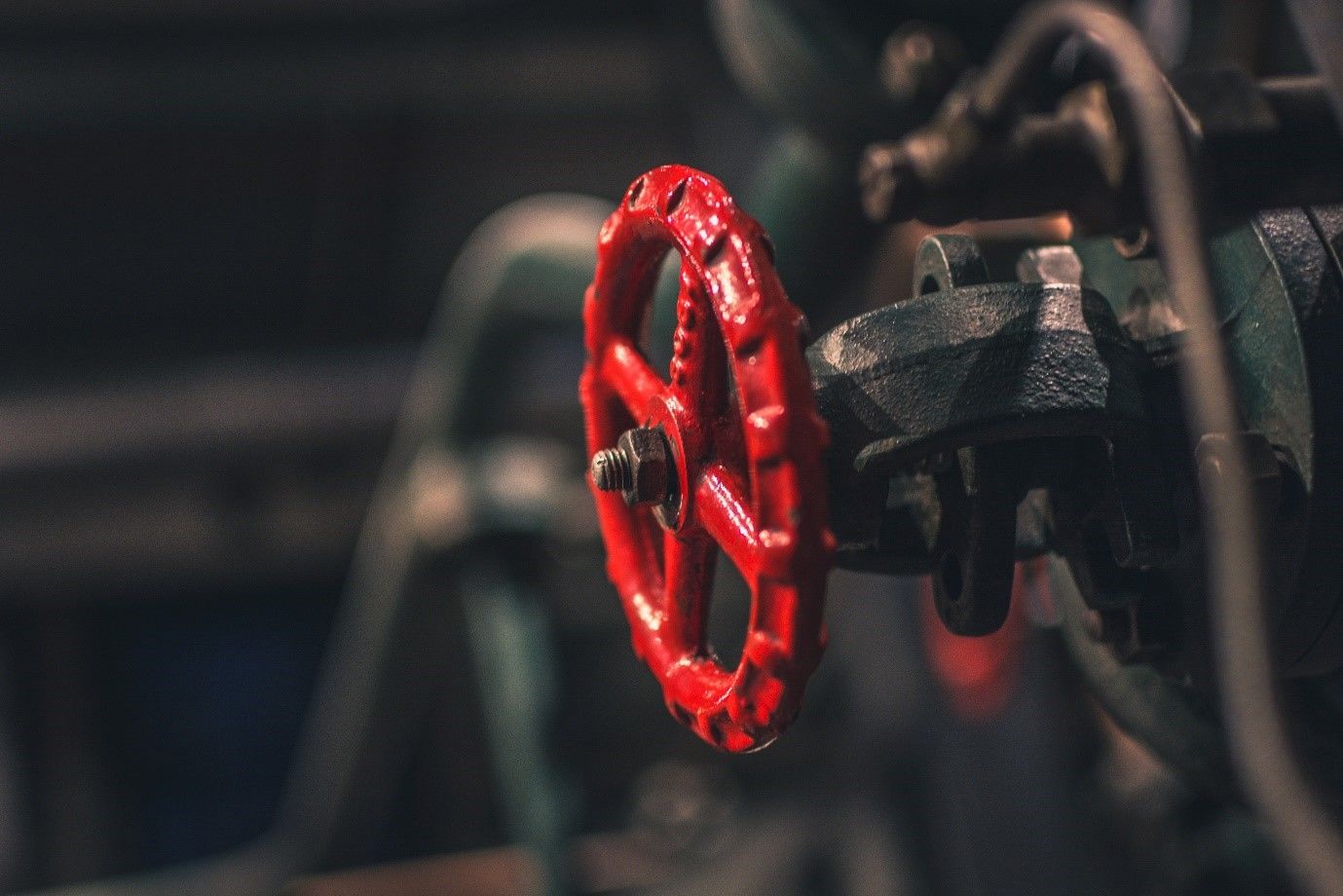

The sleeves are press-fitted and centered into the housing ends by socket covers, which get squeezed to control the flow. The sleeve is made of corrosion-resistant materials, such as elasticised reinforced rubber or PTFE. Cast iron is used to make the body of the valve. Pinch valves are an economical equipment and have a simple design. They can also be operated by actuators, such as solenoid, hydraulic, pneumatic, and electric motors. Besides air, mechanically operated pinch valves exist, such as clamp or handwheel valves and pneumatic valves. The handwheel valve is turned on and off using a handwheel. A pneumatic valve is controlled by compressor bars that pull the sleeve open or close; the air is supplied to pull the bars open as it works on a spring return mechanism. You may be wondering what are pinch valves used for? So, let's cover that.

What Are Pinch Valves Used For?

Many industries use pinch valves such as water, mineral processing, chemical, beverage, pharmaceutical, wastewater, medical, and ceramic. Pinch valves are reliable, cost-effective, and easy to use in many different applications across many markets. They have fewer additional parts and do not wear and tear much. They are used in pipelines to control the flow of abrasive media and are resistant to clogging. The media that flows through pinch valves can include both liquids such as water, chemicals, food, and solids. Pinch valves are good in handling slurries where the solid media might otherwise coat the mechanical workings of other valves. The solid media can include granules, powders, pellets, chippings, fibers, slurries, and many aggressive products.

In the food, beverage, and medical industry, their non-contact application protects food from contamination. Pinch valves are also applied as single-use disposable systems, which can be added in without disrupting the process, and this is especially beneficial for laboratories and the pharmaceutical industry.